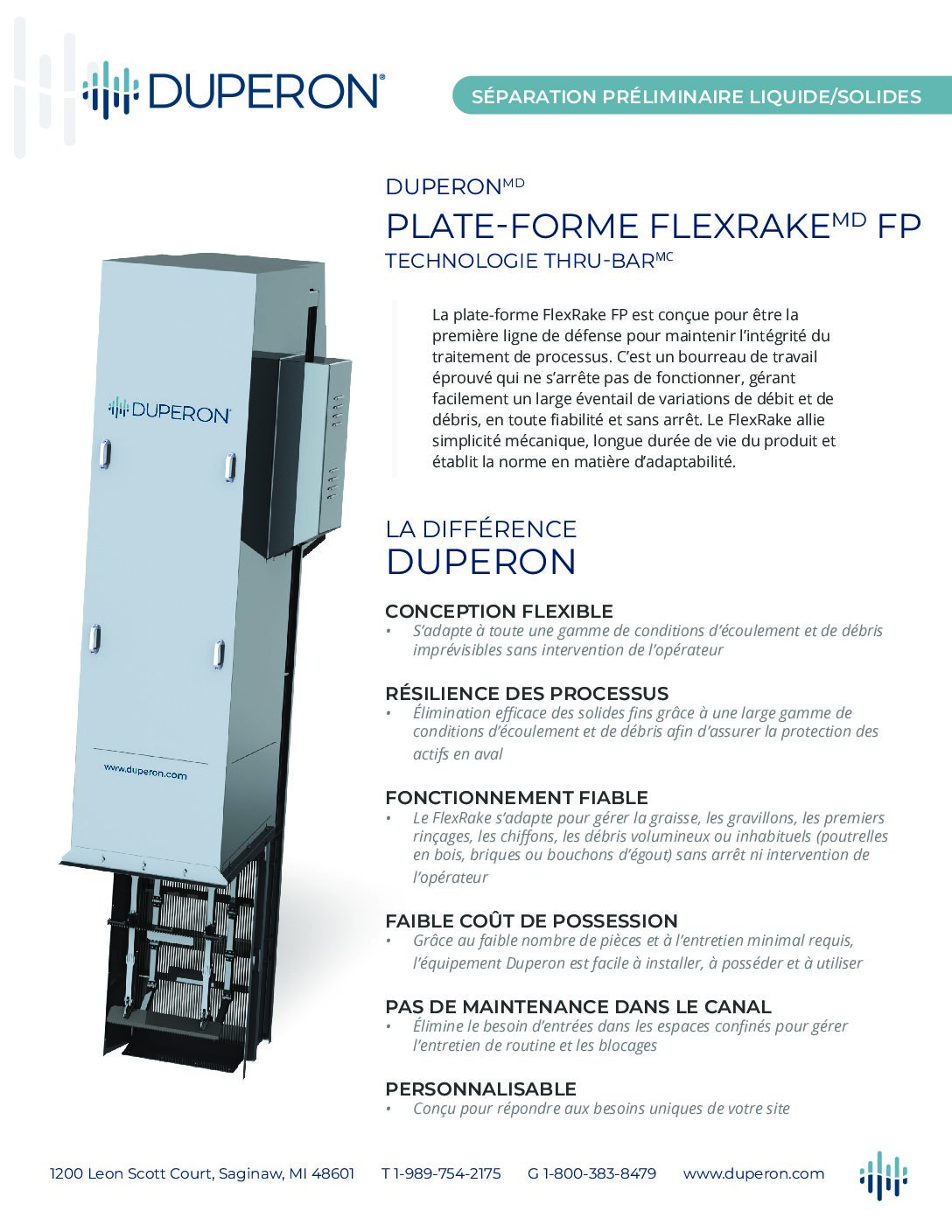

FlexRake® FP

Full Penetration Coarse Screen

greater than ½ in openings

The workhorse that set the standard for simplicity in the water and wastewater industry

For difficult-to-capture debris

The FlexRake® Full Penetration (FP) model offers multi-rake coarse screening for openings greater than ½ inch. It combines rugged Adaptive Technology™ from the FlexRake’s flood control origins and is specifically engineered to manage sticky or difficult-to capture debris, making it ideal for wastewater and industrial applications.

The FlexRake has evolved to meet the requirements of multiple industries. Wherever applied, it is a workhorse that just keeps running. The inherent value of the FlexRake is its simplicity: long product life, low cost of ownership, and adaptability to a range of site conditions (varied flows, debris types, and volumes). Duperon Corporation is continuously reinventing what is possible for simplicity in screening.

Wastewater & Collection Systems Applications:

- Preliminary treatment

- Headworks

- Pump stations

- Lift stations

- Combined sewer overflows

- Prisons

Industrial Applications:

- Pulp and paper mills

- Food and beverage

Open Channel Applications:

- Power generation

- Raw water intakes

- And other applications where debris is highly variable or difficult-to-capture.

The Duperon®

Difference

The Duperon®

FlexRake® FP

Flexible design

Adapts to a range of unpredictable flow and debris conditions without operator intervention

Process resilience

Effective coarse solids removal through a broad range of flow and debris conditions so downstream assets remain protected

Reliable operation

The FlexRake FP adapts to handles grease, grit, first flushes, rags, large or unusual debris (2×4’s, bricks or sewer plugs) without shutdown or operator intervention

Low cost of ownership

With few parts and minimal maintenance required, the FlexRake FP is easy to install, own, and operate

No in-channel maintenance

Everything is serviceable from the deck, eliminating confined space entries, jamming and routine in-channel maintenance

Customizable

Engineered to fit the unique needs of your site

You’ll like

working with us

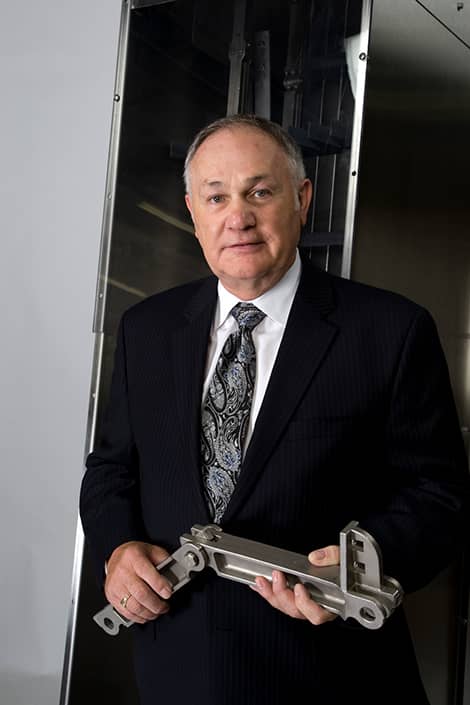

Our biggest benefit? We eliminated approximately 15 confined space entries a year

Randy Sommers

Superintendent, City of Monroe, MI

(Retired)

Our story is simple

Our Story Is Simple

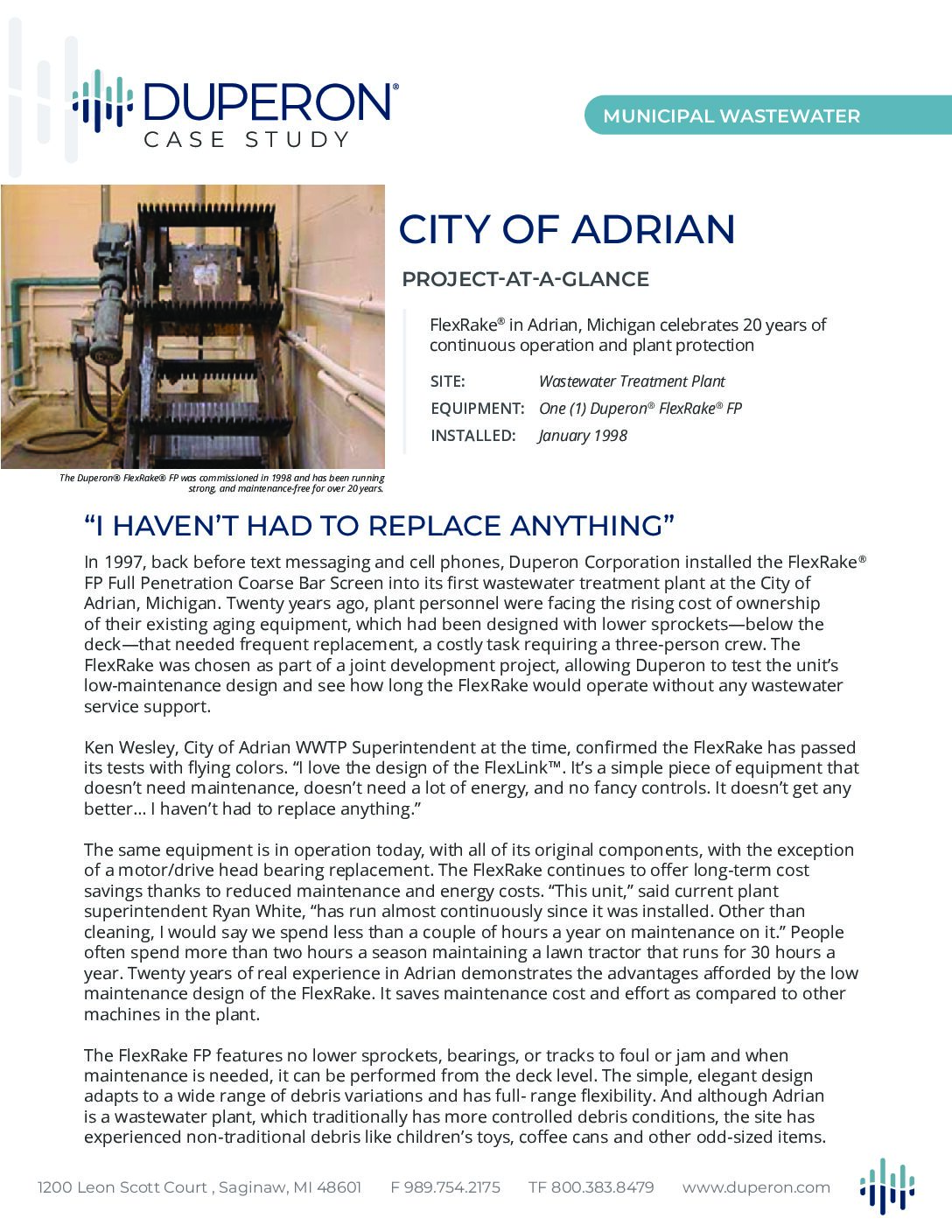

Duperon entered the municipal market in 1997 when wastewater operators saw the FlexRake® at a conference. Like many cities, the City of Adrian wastewater plant was facing the rising cost of ownership of their existing aging equipment. Their bar screen was designed with lower sprockets—below the deck—that needed frequent servicing and replacement. This was a costly task that required a confined space entry and a three-person crew. Seeing the obvious simplicity of the FlexRake design, and the lack of underwater sprockets, Duperon and the City of Adrian entered into a pilot agreement in 1998– that became an enduring partnership. More than 20 years later, that same unit (plus two others) are still in operation, running 24/7 and have set the standard for simplicity in the water and wastewater industry.

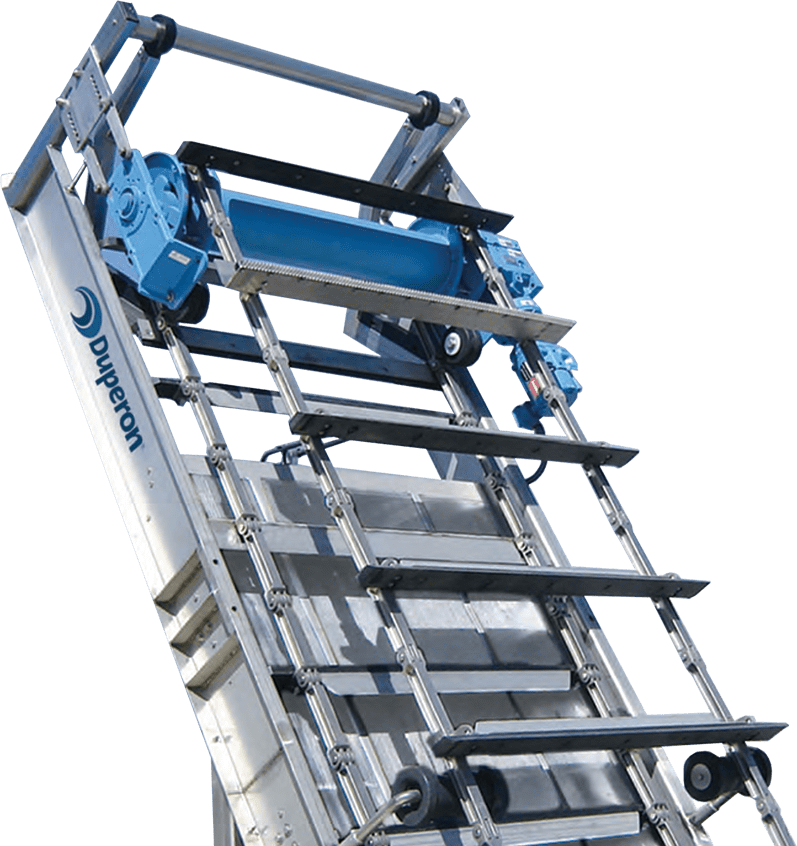

Description

The FlexRake® FP is a front-clean, front-return, mechanically cleaned bar screen. It features the industry-leading FlexLink™ multifunctional link system, which eliminates underwater sprockets, bearings or tracks that create a fixed path of travel and are subject to fouling and/or jamming. The groundbreaking flex/pivot action of the Duperon FlexRake is unhampered by large debris.

The FlexRake FP is a coarse screen that utilizes individually replaceable, stainless steel, rectangular bars with ⅝ inch to 4 inch openings. The UHMW-PE Thru-Bar™ scrapers eliminate accumulation by cleaning all three sides of the bar and cross members to remove hard-to-capture debris.

General Specs

| Typical Applications | Wastewater & Collection Systems Applications

Industrial Applications:

Open Channel Applications:

|

| Unit Width | 2 ft to 12 ft |

| Unit Length | 10 ft to 100 ft |

| Bar Openings | ⅝ in to 4 in |

| Bar Shape | Rectangular Bar |

| Scraper Configuration | UHMW-PE Thru-Bar™ scrapers that clean all sides of the bar and the cross member |

| Material of Construction | Available in 304 or 316 Stainless Steel |

| Flow Capacity | Designed to your site |

| Cleaning Frequency | 1 discharge/minute on low

4 discharges/minute on high |

| Lifting Capacity | 1000 lbs

3000 lbs option available |

| Angle of Installation | Vertical to 45 degrees, dependent upon site conditions |

| Typical Motor | ½ hp inverter duty, explosion proof |

| Standard Controls | Packages range from simple start/stop to sophisticated automation.

Motor overload protection provided. |

| Operation Options | Continuous/Manual

Automatic with timer, float, SCADA, differential/high-level sensing options with I/O as needed |

Key Features

Industry-leading FlexLink™ eliminates lower sprockets, submerged bearings and tracks

FlexLink multifunctional link system has ultimate strength of 60,000 lbs with unmatched durability

Full-Range Flexibility adapts to debris variations; from grit and grease to hard hats and sewer plugs

Jam-Evasion™ Technology lifts or pivots to process large debris without shutdown or jamming

High-capture Thru-Bar™ cleaning cleans all three sides of the bar and the cross member

Fractional horsepower motors used for energy efficiency

5 year warranty for wastewater applications

Everything is serviceable from the deck to eliminate in-channel maintenance and confined space entries

Schematic

Photo Gallery

Case Studies

City of Adrian Case Study

FlexRake® in Adrian, Michigan celebrates 20 years of continuous operation and plant protection

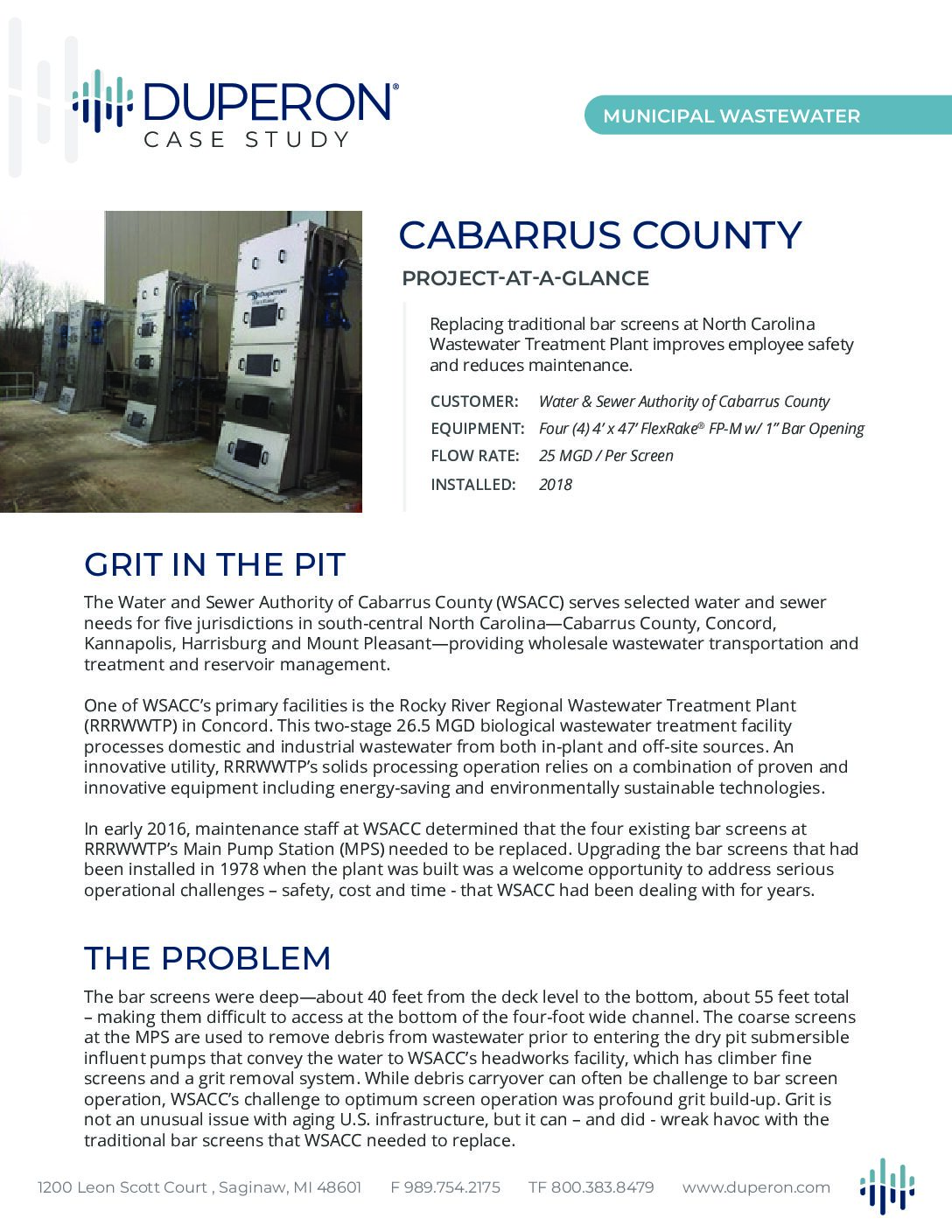

Water & Sewer Authority of Cabarrus County

Replacing traditional bar screens at North Carolina wastewater treatment plant improves employee safety and reduces maintenance.

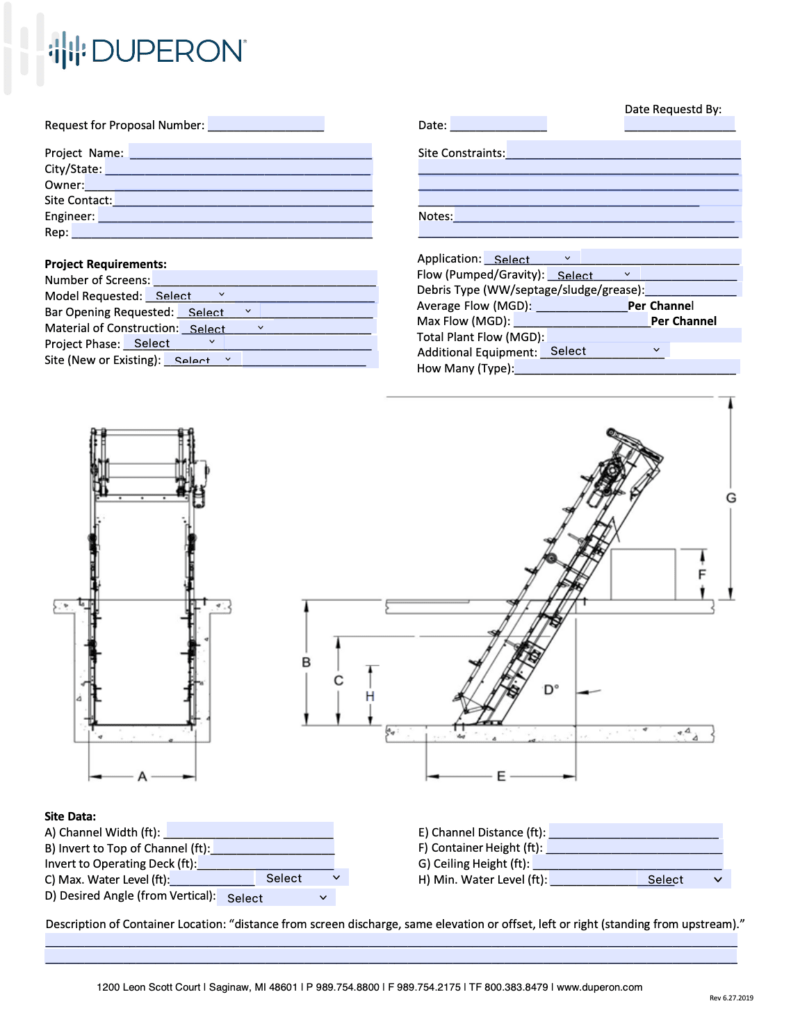

RFQ form

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.