FlexRake IQ®

Responsive Resiliency

A simple solution to smarter raking for responsive resiliency

A smarter way to screen

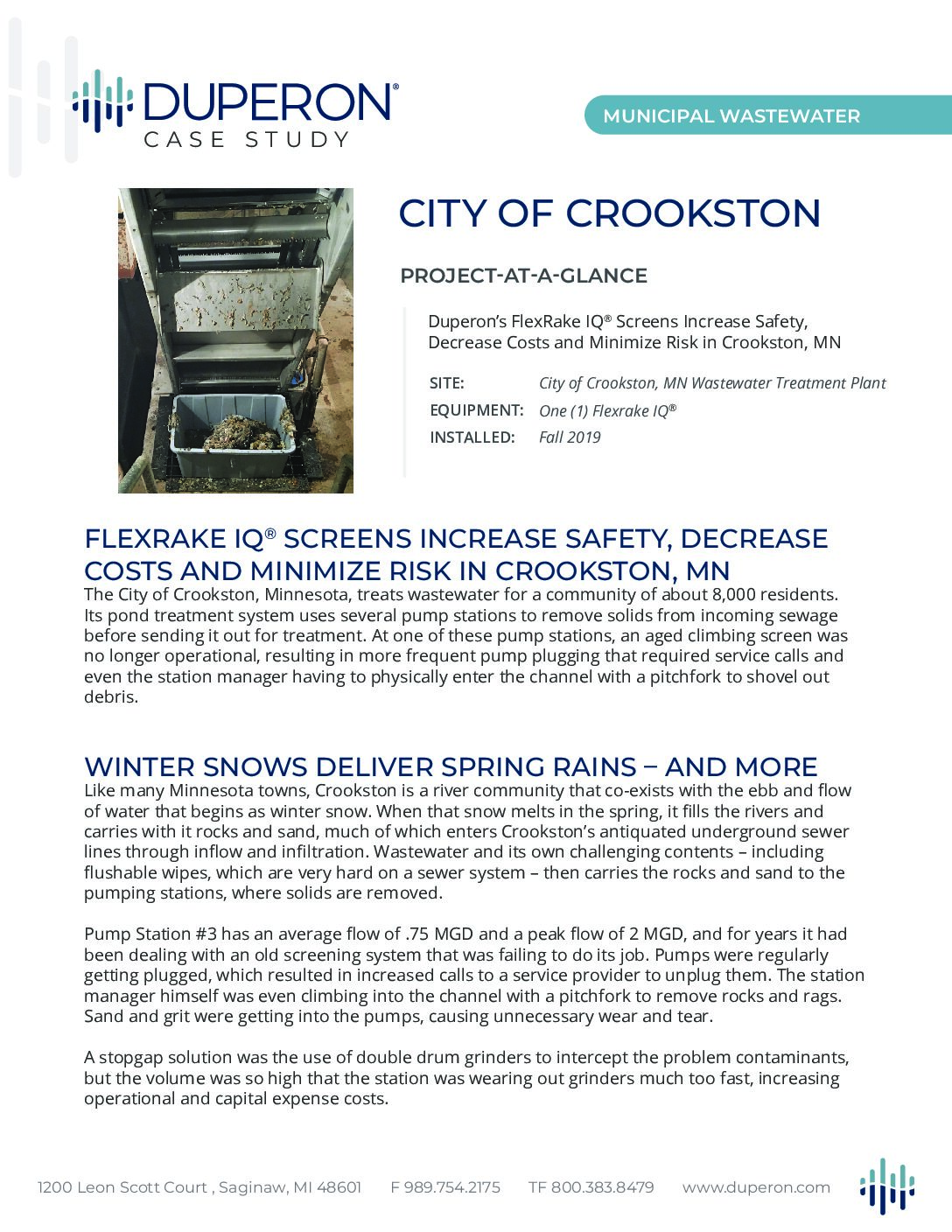

Our customers are experiencing increased demands and looking for more resilient solutions. One-hundred-year storms are occurring more frequently with bigger peaking events. There is increased inflow and infiltration (I&I) from aging infrastructure. “Flushable” wipes, grit and first flush debris add stress on treatment systems. Even the coronavirus pandemic is changing wastewater composition and diurnal flow patterns. Duperon recognized systemwide resilience begins at the headworks and a new level of raking was required to meet today (and tomorrow’s) plant challenges.

Introducing the new FlexRake IQ®

An intelligent screening system that knows what to do and when to do it.

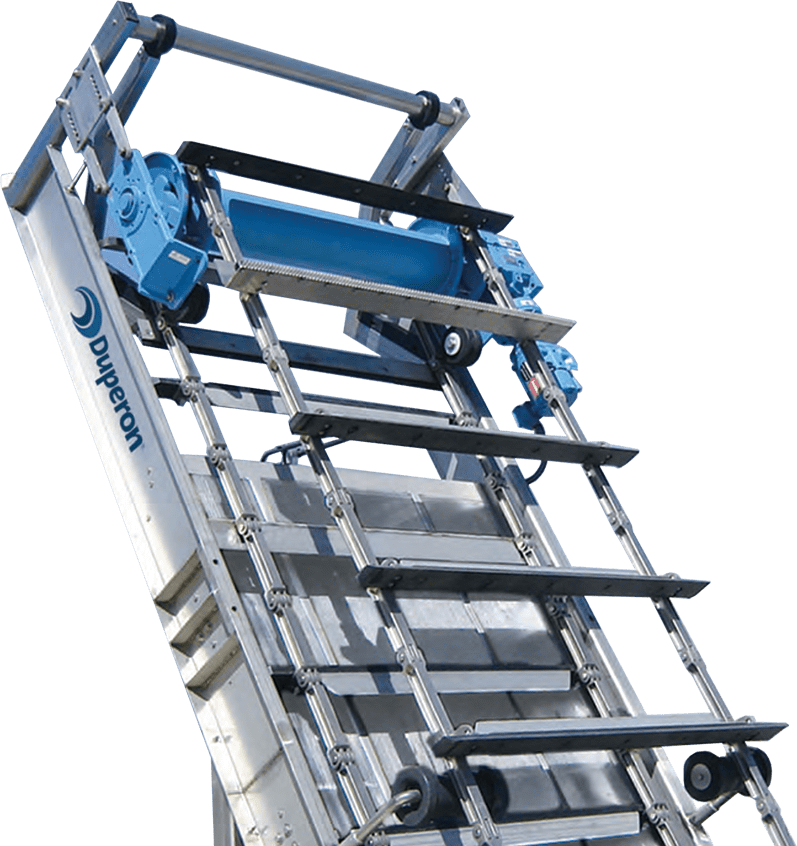

Designed with a patent-pending sequence technology that delivers 4 times greater debris removal. The FlexRake IQ enhances solids handling by sensing conditions and speeding up – or slowing down – to accommodate changing debris and flow in real time. The scrapers have an enhanced tooth profile and unique collection geometry that handle stones and remove solids cleaned at the higher speed. Large debris is still managed without shutdown and the re-imagined FlexLink™ system ensures that scrapers return to cleaning the screen field faster.

The FlexRake IQ makes these adjustments automatically, without operator intervention. System function returns to normal as soon as operating conditions allow, extending the life of mechanical components.

The original FlexRake® transformed preliminary liquids/solids separation with its simple design that had no in-channel maintenance and ability to adapt to debris. In the tradition of Duperon simplicity, we are now offering a new level of resilient screening. With the FlexRake IQ, we have reimagined components and sequencing to improve screening during normal flow while sensing and responding to solids events…without sacrificing the simplicity, ease of operation, and low cost of ownership associated with Duperon technology.

The FlexRake IQ: designed to deliver a greater range of flexibility over the broadest range of conditions.

Applications:

- Pump stations

- Influent bar screens

- Municipal headworks

- Combined sewer overflow facilities

- Industrial applications

The Duperon®

Difference

The Duperon®

FlexRake IQ®

The FlexRake IQ focuses on Smart Raking enhancements:

Automated, real-time response

Intuitive sequence of operations automatically responds to changing flow and debris conditions

Optimized hydraulic performance

Ideal during heavy solid loading events or first flush events

Increased debris removal

Up to 4x the debris removal capacity

Enhanced debris management

Improved grit/rock handling

Process resiliency

With reliable continuous cleaning; Jam Evasion™ Technology and rapid re-engagement, the FlexRake IQ can remove large debris without disruption and re-enter into the bar screen quickly to avoid blinding, flooding, and bypassing

Long product life

The re-imagined FlexLink™ is designed for long life at higher speeds

Description

A new level of resiliency is required to meet today’s known plant challenges and prepare for tomorrows. The FlexRake IQ Platform tackles high peaking factors due to extreme weather and menacing debris like “flushable” wipes, first flushes and settled solids. This is accomplished by system improvements and a patent-pending sequence of operations that automatically responds in real-time to optimize the screen field.

The re-imagined design of the FlexRake IQ focuses on smart enhancements to the raking device to manage heavy solids loading events with 4x increased debris removal capacity, improved grit and rock handling, and greater solids capture.

The FlexRake IQ is an intelligent screening system that knows what to do, and more importantly when to do it without operator intervention.

General Specs

| Typical Applications & Key Considerations |

Other site considerations:

|

| Unit Width | 2 ft to 10 ft |

| Unit Length | Up to 100 ft |

| Bar Openings | ⅛ in or greater |

| Angle of Installation | Vertical to 45 degrees |

| Material of Construction | Standard: 304 SSTL. 316 SSTL available |

| Typical Motor | 1 hp |

| Cleaning Frequency | Entire screening field cleaned every 7 seconds at max speed |

| Standard Controls | Base packages range from simple start/stop to sophisticated automation |

Key Features

Patent-pending Smart LogIQ™ Sequence of Operations: Intelligently monitors and automatically adjusts screen operations to changing channel conditions

Re-engineered FlexLink™: designed for additional speed capabilities

Rapid re-engagement: removes large/irregular debris without shutdown and quickly returns the scraper into the bar screen to keep it clean

Re-engineered scraper design: provides 4x debris removal capacity and increased strength

Re-configured bar screen design: allows for lowest possible engagement and improved grit/rock and settled debris handling

All the benefits of the Original FlexRake platform

- Reliable

- Jam Evasion™ Technology

- Low maintenance

- Adaptable to debris

- Low cost of ownership

- Over 25 years of application experience

- Learn more

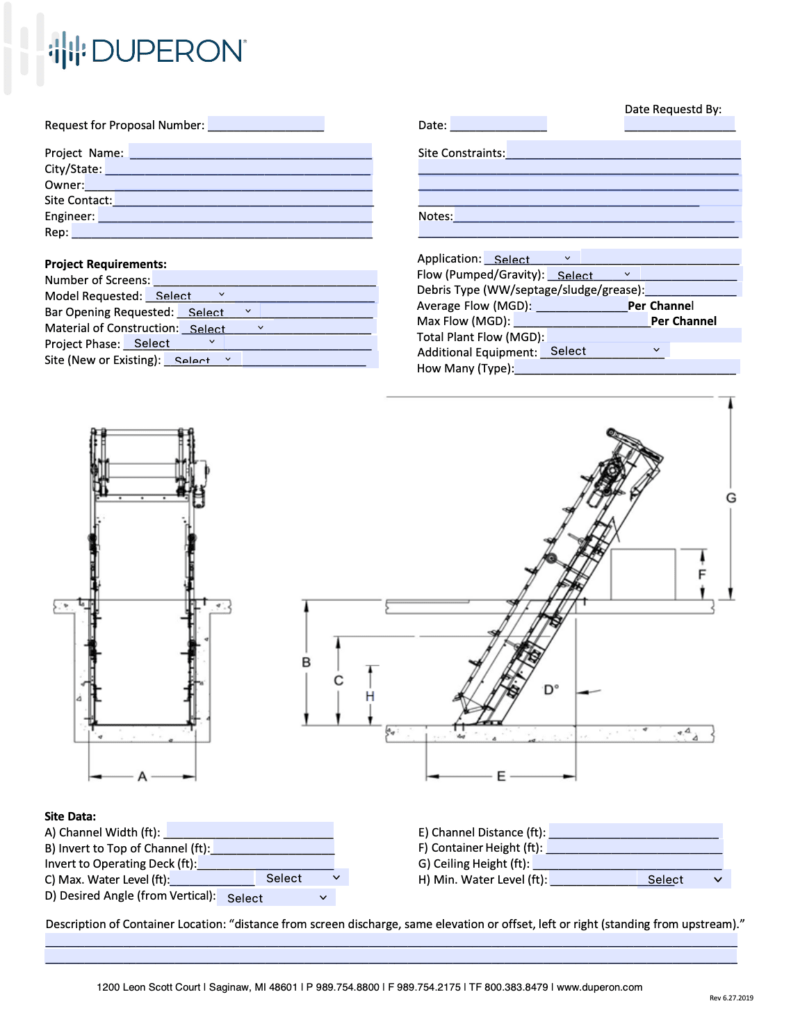

Schematic

Photo Gallery

Case Studies

Related Products

RFQ form

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.