Low Flow System

Designed for sites with average flow of 1MGD or less

Complete screening and solids handling system

Cost-effective Screening And Compacting System For Low Flow Applications

A pre-engineered, fully automated system for wastewater applications with average flows of 1 MGD or less; and up to 4 MGD. The proven FlexRake technology is paired with a perfectly-sized washer compactor to seamlessly remove, clean, compact and discharge screenings 5 ft. (centerline) in any direction.

Many small and rural communities rely on decentralized treatment systems or operate wastewater facilities that have average flows of 1 MGD or less. This sized plant serves most of the US population. According to the EPA, these communities also face financial resource challenges, workforce issues and lack cost-effective treatment.

The Low Flow System solves these challenges by providing a simple, affordable, and reliable automated bar screen and solids handling packaged system for preliminary treatment. It incorporates proven FlexRake® Adaptive Technology™ and a washer compactor specifically designed for this application and price point, maximizing value and performance.

Applications:

- Municipal wastewater

The Duperon®

Difference

The Duperon®

Low Flow System

Fully automated solution

Simple and cost-effective mechanical bar screen and washer compactor for low flow sites

Superior washing and compacting performance

80% volume reduction, 60% weight reduction to save landfill disposal costs

Adaptable design

Adjusts to a range of unpredictable flow and debris conditions using proven FlexRake® Adaptive Technology

Safety factor

Designed to handle 4 MGD peaking events to provide peace of mind and performance during wet weather

Low cost of ownership

With few parts, simple design and minimal maintenance, the FlexRake Low Flow System is easy to install, own, and operate by your crew

Designed for duty

Pre-engineered and sized to perform in channels, flows, and conditions for small communities.

Compact system

Low profile, integrated system with footprint half the size of in-channel auger style equipment

Built-in flexibility

Flexible pre-engineered design with options to fit your site needs

Our solutions are simple

Our Solutions Are Simple

More than 80% of treatment plants in the United States are rated for 1 MGD or less. Small community wastewater systems are often resource and budget constrained but their headworks still plays an important role in the treatment process.

The Low Flow System was invented to offer a simple raking device that solves the challenges of

- Static bar screens that require manual cleaning

- High-maintenance cylindrical basket screens

- Unsatisfactory cleaning and compaction of screenings

Small communities no longer have to compromise between manual cleaning, complex systems that require frequent maintenance or subpar washing and compacting. The Low Flow System provides another option for simple, affordable, and reliable automated bar screening and solids handling for low flow sites. It incorporates proven FlexRake® Adaptive Technology™ and a washer compactor specifically designed for this application and price point, maximizing value and performance.

Description

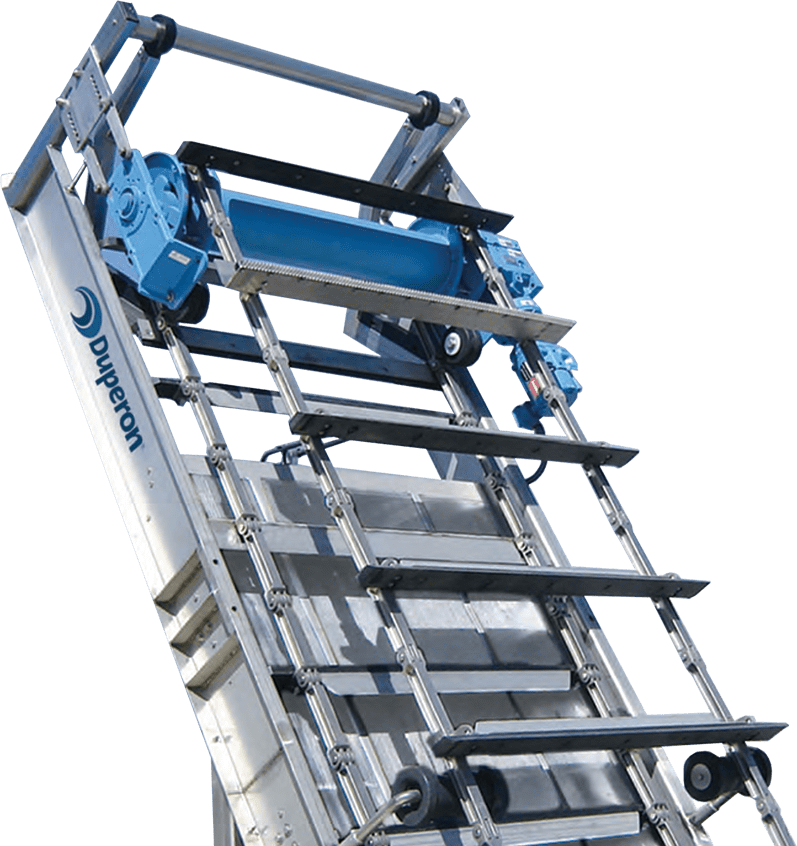

The Low Flow System is a pre-engineered system that combines a Low Flow and a single auger washer compactor for sites with average flows under 1 MGD and peak up to 4 MGD. With ¾ hp sites can screen, wash and compact.

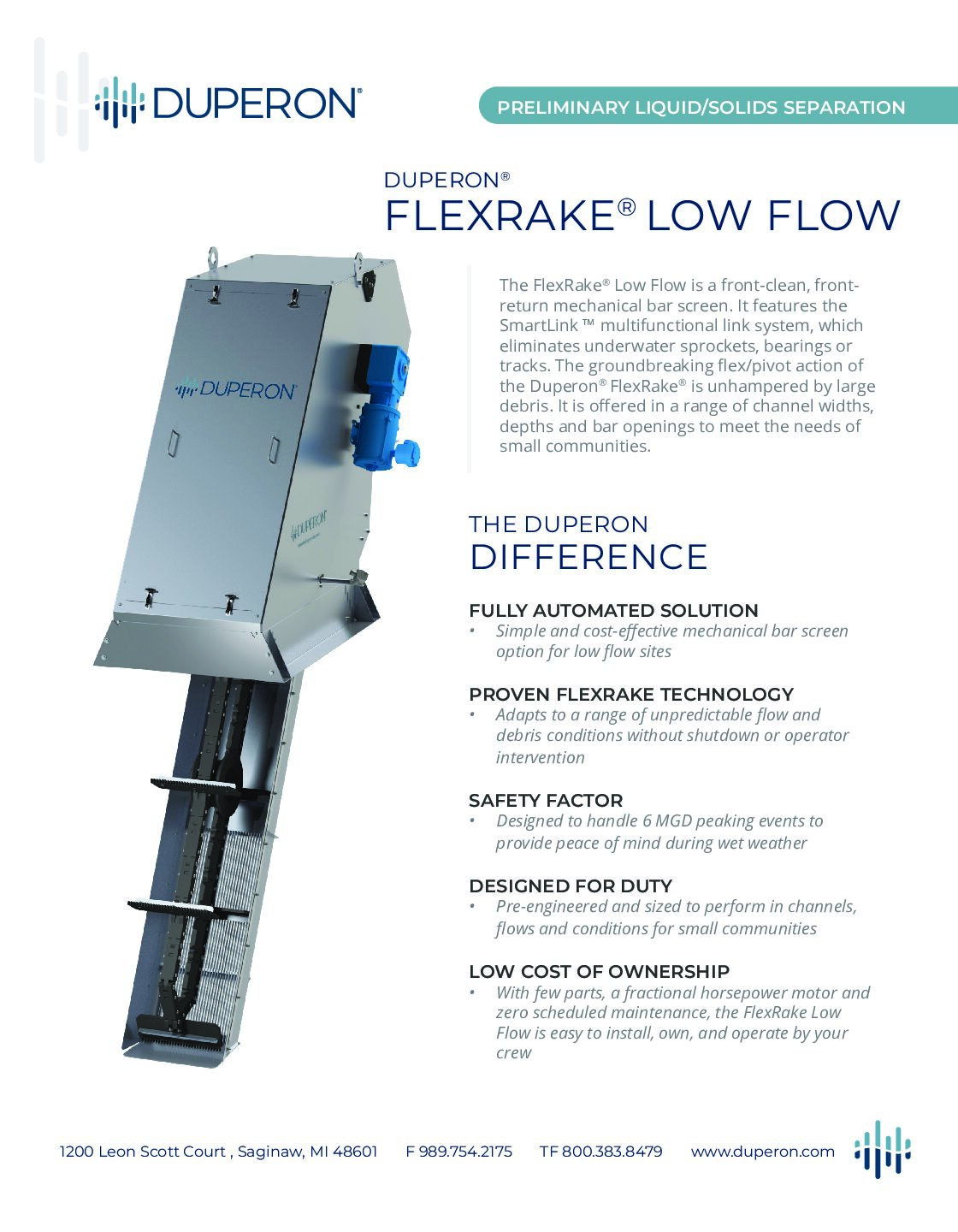

The Low Flow is a front-clean, front-return mechanical bar screen. It features the SmartLink™ multifunctional link system, which eliminates underwater sprockets, bearings or tracks that create a fixed path of travel and are subject to fouling and/or jamming. The groundbreaking flex/pivot action of the Duperon FlexRake is unhampered by large debris. It is offered in a range of channel widths, depths and bar openings to meet the needs of small communities.

The pre-engineered Low Flow Washer Compactor is a perfect fit in size and capacity to receive screenings from the FlexRake Low Flow bar screen. It consists of a single auger with a floating bearing design to self-center and accommodate irregular debris. A self-cleaning strainer eliminates maintenance-intensive brushes. The washing chamber rinses screenings and returns fecal matter to the channel via an anti-clogging drain. The weight and back pressure from the debris in the chute generate compaction – there is no fixed sized compaction. The Low Flow Washer Compactor is integrated to run in coordination with the Low Flow bar screen (non-batch processing). Please see accessories tab for information on optional baggers and freeze protection.

General Specs

| Typical Applications | Municipal wastewater |

| Average Flow Capacity | 1 MGD or less |

| Peak Flow Capacity | 12 in wide = 2.5 MGD, 18 in wide = 4.0 MGD, 24 in wide = 6.0 MGD |

| Bar Opening Options | ¼ in, ½ in, ¾ in, 1 in |

| Channel Width Options | 12 in, 18 in, 24 in

*Custom closeouts available for other sizing that meets the flow requirements of the Low Flow |

| Channel Depth Options | 2 ft to 6 ft |

| Maximum Water Level | 30 in |

| Minimum Water Level | 0 in |

| Material of Construction | Available in 304 or 316 Stainless Steel

UHMW Scrapers UHMW SmartLink™ |

| Lifting Capacity | 500 lbs |

| Discharge Rate | Every 24.7 seconds |

| Typical Motor | ¼ HP

1 PH/115 or 230 VAC 3PH/240 or 480 VAC TEFC, inverter duty |

| Standard Controls | Emergency Stop

On-Off Run Monitoring (Dry Contact) *Explosion proof controls available |

General Specs

| Typical Applications | Municipal wastewater |

| Average Flow Capacity | 5.5 cu.ft/hr |

| Peak Flow Capacity | 8 cu.ft/hr |

| Discharge Chute | Positional up to 5 ft centerline in any direction |

| Material of Construction | Available in 304 or 316 Stainless Steel

UHMW Auger Supports |

| Typical Motor | ½ HP

1 PH/115 or 230 VAC 3PH/240 or 480 VAC explosion proof, inverter duty |

| Utility | 1 PH/115 or 230 VAC

3 PH/240 or 480 VAC |

| Wash Water | Filtered Effluent Screened at/below 150 Micron

100 Mesh Screen |

| Water Supply Connection | ½ in NPT Female Connection or

GHT ¾ in Female Fitting for Standard Garden Hose |

| Water Consumption | 3GPM – 6GPM |

| Water Pressure | 40 PSI – 60 PSI |

| Drain Connection | 3 in NPT |

| Dry Solids | Up to 60% |

| Mass/Weight Reduction | Up to 70% |

| Volume Reduction | Up to 80% |

| Odor/Fecal | Significantly Decreases Odor/Fecal

Compacted Screenings Pass Paint Filter Test |

Key Features

Pre-engineered system that has flexibility: discharge chute, drain connection and motor location options to fit your site

FlexRake Low Flow:

Includes a built-in safety factor to handle flows up to 4 MGD peak

Standard features include: easy controls, spray wash for screenings, all stainless steel construction

Tear-drop shaped bars provide highest efficiency in the industry; 25%-50% more efficient (depending on the bar opening)

Thru-Bar™ scrapers clean all three sides of the bar and cross member

Proven Duperon® FlexRake® technology: no lower bearings, sprockets, jam points or confined space entries

UHMW Low Flow SmartLink™ is completely corrosion-resistant, provides long life and is self-lubricating material

UHMW Low Flow SmartLink™ allows for “dry” operation which is ideal for low flow sites with varying water levels since there is no minimum depth required

Integral enclosure provides easy installation, access and viewing

Low Flow Washer Compactor:

Customizable speed and wash settings to optimize cleaning based on site conditions

Over-sized hopper capacity reduces overflow potential

Anti-clogging drain connection

Discharge 5 ft. CL in any direction, even upstream

Floating bearing design self-centers and accommodates irregular debris without binding

System engineered for minimum footprint

The Bagger System attaches to the discharge chute for applications where bag dispensing and odor control are required. Included is a 90 meter length of continuous feed bags.

This flexible Drop Sleeve is an economical way to direct and contain downward debris discharge. Also used where waste container hauling may cause damage to metal discharge chutes.

The discharge chute can be thermally protected from cold temperatures with the addition of the Heat Blanket with integral heat trace.

Schematic

Photo Gallery

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.