FlexRake® FSB

Fine Screen Boutique

openings from 0.020 in to 0.125 in

The advantage of FlexRake® Adaptive Technology™ for specialized fine screen applications

Cost-effective screening for boutique wineries and industrial applications

The FlexRake® Fine Screen Boutique (FSB) model is a completely contained, pre-engineered pipe-to-pipe solution for food processing, (boutique) wineries, and other applications. It utilizes a T-shaped Wedgewire screen that can filter from 0.020 to 0.125 inches and is specifically designed to efficiently manage process byproducts and wastewater.

The FlexRake Fine Screen Boutique provides a robust option for simple, affordable, and reliable automated bar screening for small food and beverage applications. It incorporates proven Duperon Adaptive Technology™ specifically designed for this application and price point, maximizing value and performance.

Applications:

- Boutique wineries

- Food processing

- other food and beverage applications

The Duperon®

Difference

The Duperon®

FlexRake® FSB

Reduces treatment costs

Effective fine solids removal lowers BOD (biological oxygen demand), the amount of treatment chemicals needed, debris loading on downstream processes or surcharges for high-strength wastewater

Bottom-line cost savings

With few parts, minimal maintenance, and long product life, the FSB is easy to install, own, and operate

Flexible design

Adapts to a range of known site conditions along with unpredictable debris and flow process peaks, eliminating the need for graduated screens

Efficient

Uses fractional horsepower consumption and no water for CIP (clean-in-place) required

Designed for duty

Pre-engineered to perform in flows, conditions, and price point for boutique wineries and other industry applications

All-inclusive package

Compact system in stainless steel tank with built-in bypass, integral enclosure, and controls

Description

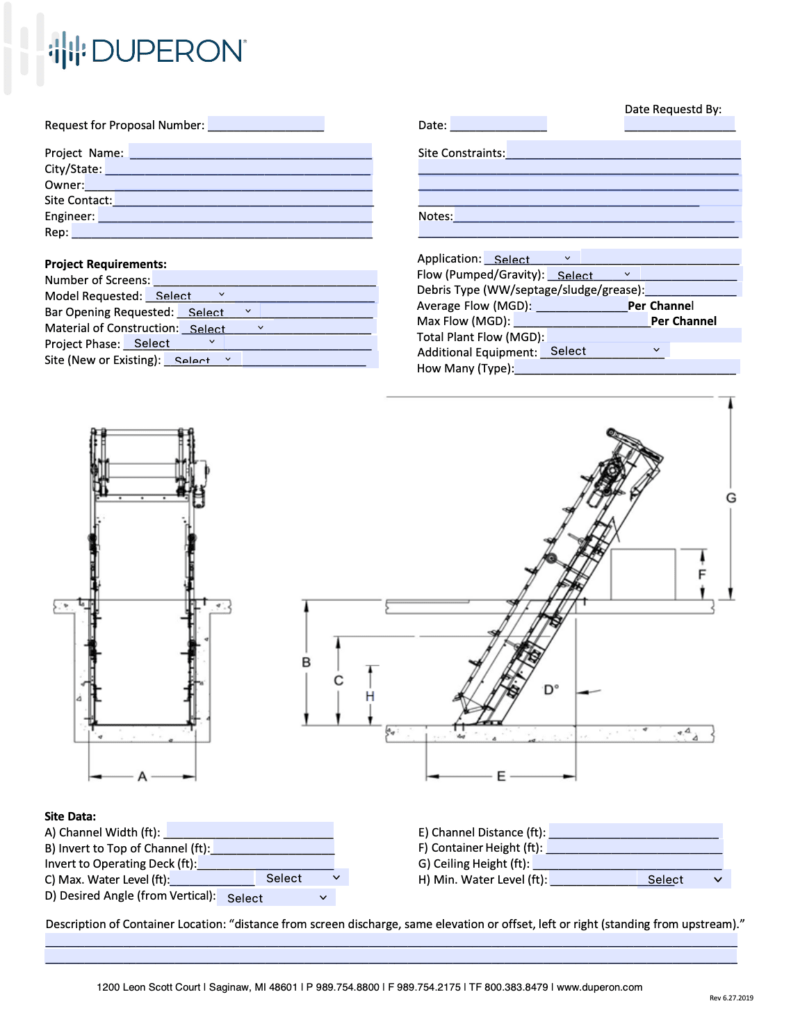

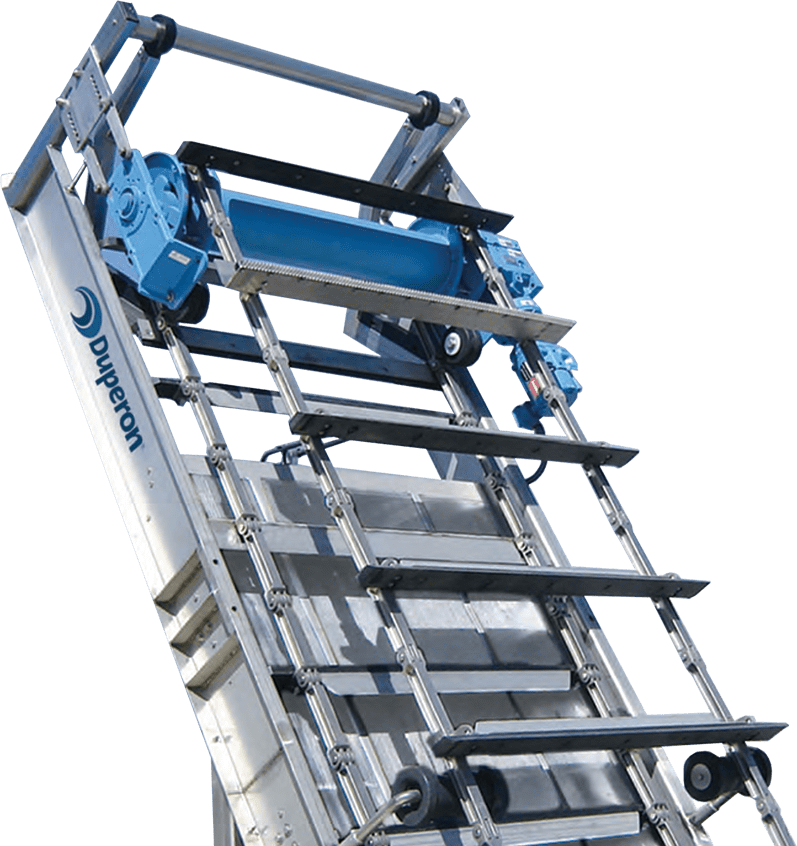

The FlexRake® FSB is a front-clean, front-return, mechanically cleaned bar screen in a pre-engineered packaged 2 ft x 4 ft stainless steel tank. The compact model includes an 8 inch pipe-in, pipe-out connection, built-in overflow bypass, enclosure, and controls. It features the industry-leading FlexLink™ multifunctional link system, which eliminates underwater sprockets, bearings or tracks.

The FlexRake® FSB is constructed of a stainless steel wedgewire screen (0.020 – 0.125 inch openings) and UHMW-PE scrapers designed to your specific application.

General Specs

| Typical Applications |

|

| Tank Dimensions:

Width |

2 ft |

| Discharge Height | 3 ft – 5 in |

| Wedgewire Screen Openings | 0.020 in, 0.040 in, 0.060 in, 0.100 in, or 0.125 in |

| Scraper Configuration | UHMW scrapers consist of squeegees, beveled edges or brushes depending on application |

| Material of Construction | Available in 304 or 316 Stainless Steel |

| Flow Capacity | Designed to your site and velocity requirements |

| Cleaning Frequency | 1 discharge/minute |

| Lifting Capacity | 300 lbs |

| Angle of Installation | 30 degrees from vertical |

| Typical Motor | 1/4 HP 1 PH, 115/230 VAC OR 3 PH, 230/460 VAC, weatherproof motor |

| Standard Controls | Overload Protection

Variable Speed Discrete Start/Stop |

Key Features

Pre-engineered solution

Compact system to include built-in overflow bypass, enclosure and controls

Industry-leading FlexLink™ eliminates lower sprockets, submerged bearings and tracks

No water usage required

Long product life with use of SSTL and UHMW-PE durable materials

Low maintenance

Flexible design adapts to planned process peak variations as well as unexpected debris

Fractional horsepower motors used for energy efficiency

Schematic

Photo Gallery

Downloads

Related Products

RFQ form

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your screening needs

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.