SCT

Self-Cleaning Trashrack

Handles high volumes, high velocity, and all types of debris for absolute flow protection

When protecting communities, water supply, and public welfare is essential

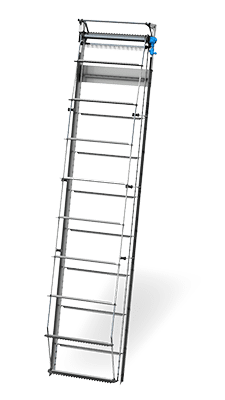

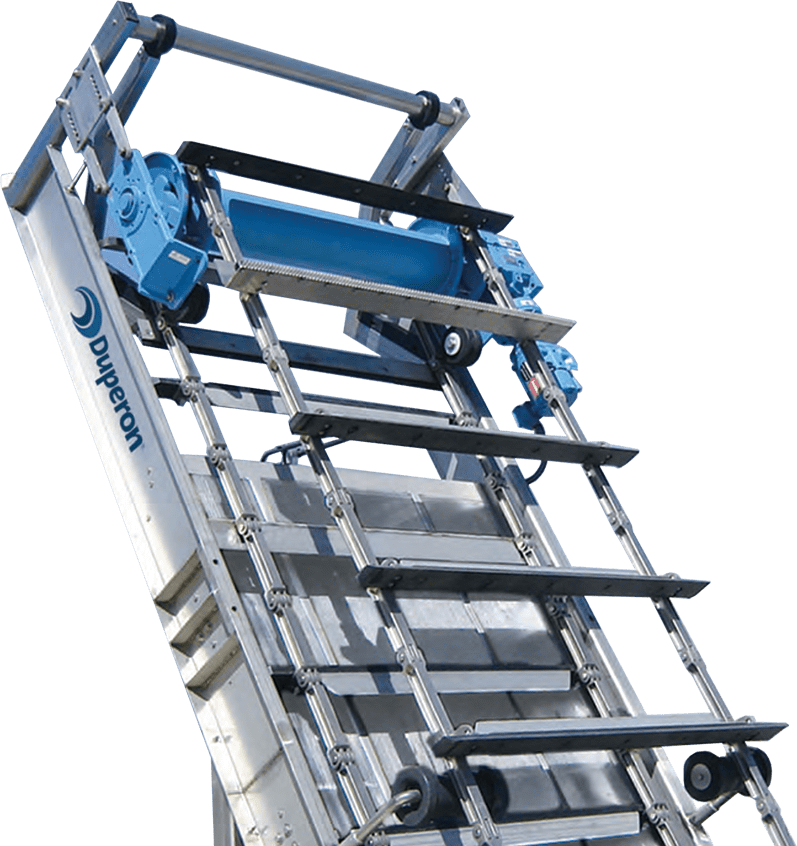

The Duperon Self-Cleaning Trashrack (SCT) is a front-cleaning, rear-return style automated screen. It is designed for tough open channel conditions where debris is large, high volume, or high velocity flows.

Its robust frame and 3000 lb lifting capacity manage everything from severe aquatic vegetation, tree stumps and automobile engine blocks. Whether the goal is flood control, uninterrupted power generation, or pump protection, this unique design assures that debris is brought to the surface automatically and continuously, without operator intervention, all at a pace that can be managed at the deck.

The SCT incorporates the natural dynamic of mat formation to optimize removal efficiencies of both small and large debris. Cleaning occurs simultaneously with multiple chains on each unit across the channel to remove the debris mats.

The Self-Cleaning Trashrack is engineered to be able to sit idle for long periods and ready to move into action when called. Redundancy is built into the design, cleaning the entire intake, with each unit independent, each chain independent and a self-tripping mechanism that means the unit can keep running even when hit hard. When looking for a key tool in building community or process resiliency, the Self-Cleaning Trashrack is your best defense.

Applications:

- Flood control

- Hydroelectric

- Co-generation

- Nuclear power plant

- Stormwater

- Water intakes

- Diversion dams

- Drainage pump stations

- Irrigation

The Duperon®

Difference

The Duperon®

SCT

Performance in the harshest environments

The SCT is ideal for sites that experience high velocities, high flows, and harsh debris conditions. With a lifting capacity of 3000 lbs, the SCT can easily handle heavy vegetation, large refuse, logs and even automobile engines and washing machines

Reliable operation

Can stand idle for long periods, yet reliably respond when a storm or debris event occurs

Ensures continuous waterflow

Multiple chains across the intake clean all of the screen all of the time. Additionally, the front-cleaning, rear-return operation provides constant flowable area to keep water moving

Continuous Cleaning

Built-in redundancy and automatic reset features avoid shutdown. Each chain operates independently and has self-tripping mechanisms that bypass debris heavier than 3000 lbs for uninterrupted cleaning

Simple

With few moving parts, no underwater bearings or sprockets, and minimal maintenance, the SCT is easy to install, own, and operate by crew

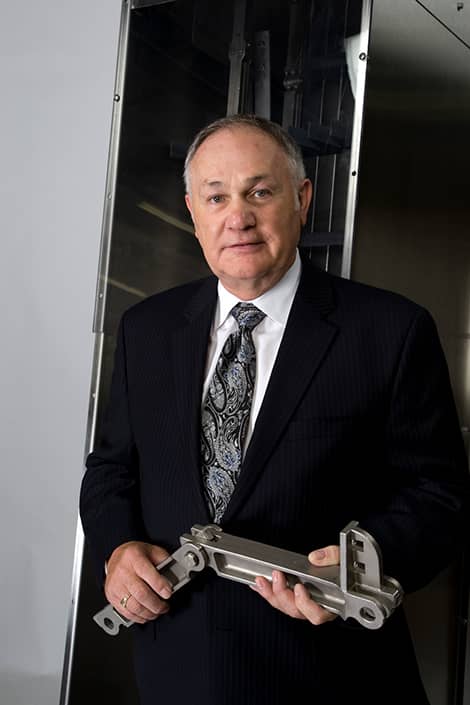

Our story is simple

Our Story Is Simple

As an inventor and manufacturer of pumps, founder Terry Duperon discovered that his customers had a problem during storm events: his pumps would shut down to avoid cavitation due to large volumes of fast-moving debris damming the bar screens. These pumps were critical to protecting neighborhoods from floodwaters. To safeguard his pumps and the communities that relied on them, Terry looked to the source of the problem and invented the Self-Cleaning Trashrack. His simple yet groundbreaking design provided pump protection that was completely reliable, cost-effective, and easy to maintain. After nearly 40 years, the first systems are still running in the field.

Today, the Duperon Self-Cleaning Trashrack (SCT) remains a dependable option for communities who need absolute flow protection. Designed to withstand the harshest storm and debris conditions, the SCT can remain unused for long periods of time and reliably operate when it’s needed most.

Description

The Duperon Self-Cleaning Trashrack is a front-cleaning, rear-return style automated screen used in severe open channel conditions where debris is large, high volume, or at a high velocity. The SCT incorporates the natural dynamic of mat formation to optimize removal efficiencies. The chains support lifting cars that simultaneously clean across the channel to remove debris.

General Specs

| Typical Applications |

|

| Unit Width | 5 ft to 10 ft |

| Unit Length | 10 ft to 100 ft |

| Angle of Installation | 30 degrees from vertical |

| Bar Openings | 2 in – 3 in

Other options available |

| Material of Construction | A36 Steel, with Duperon standard coating or

Stainless Steel also available CL40 Iron Cars 304 Stainless Steel Lifting Fingers |

| Cleaning Frequency | 7 ft/minute |

| Lifting Capacity | 3000 lbs |

| Typical Motor | 1.5 hp

1PH & 3PH options available |

| Standard Controls | Packages range from simple start/stop to full automation.

Motor overload protection provided. |

Key Features

Lifting capacity of 3,000 lbs

Can stand sdle for long periods, yet reliably start whenever a storm or rain event occurs

Built-In redundancy—each chain operates independently, even if one chain strand is out-of-service, cleaning will continue

Simple self-tripping mechanism allows debris too large or bulky to trip the lifting car rather than shut down the SCT

No underwater bearings or sprockets

Cleans all of the screen all of the time

Front-cleaning, rear-return means lifting fingers do not have to penetrate the upstream debris

Prevents debris from sliding down, accumulating and blocking screen—water flow is ensured

Schematic

Photo Gallery

Case Studies

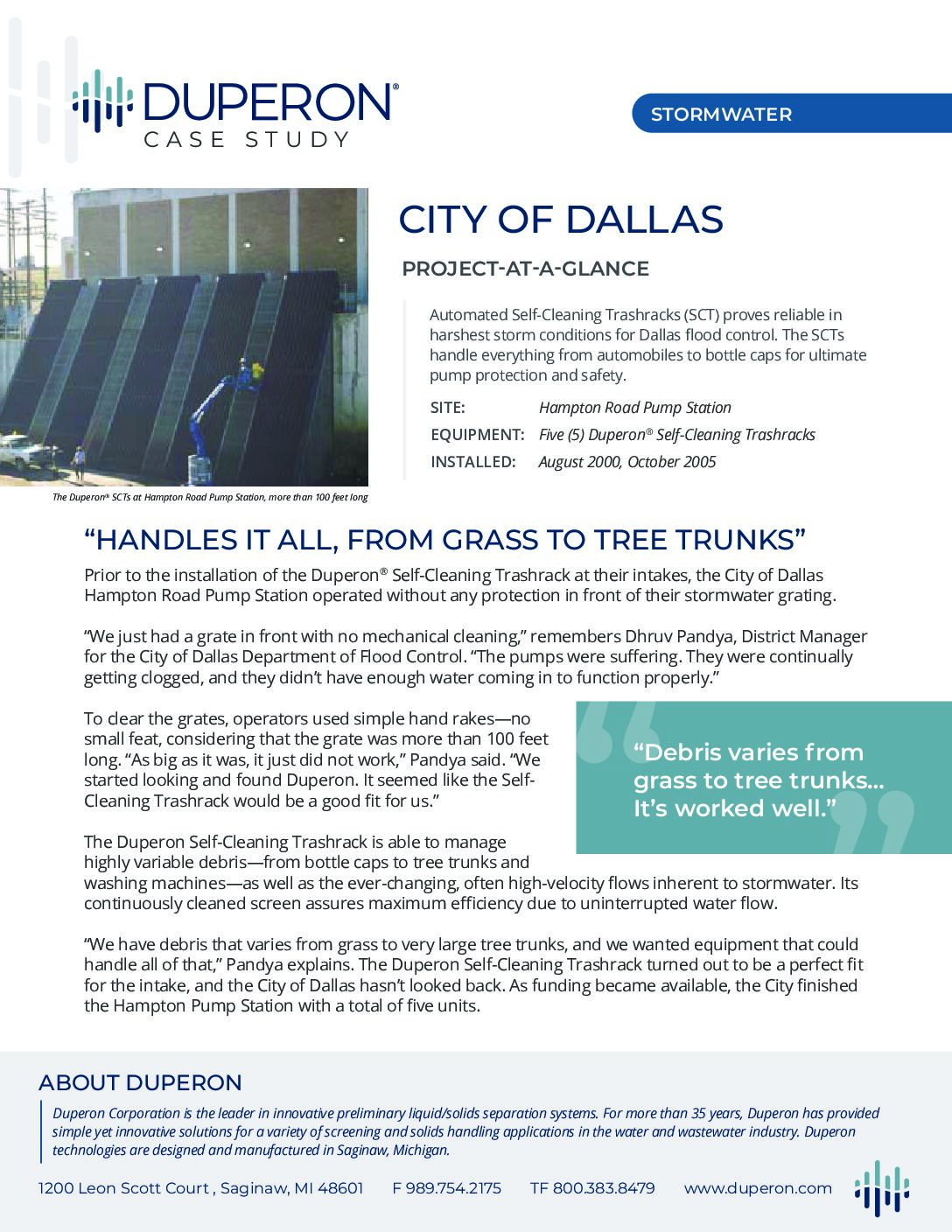

City of Dallas Case Study

Automated Self-Cleaning Trashracks (SCT) proves reliable in harshest storm conditions for Dallas flood control. The SCTs handle everything from automobiles to bottle caps for ultimate pump protection and safety.

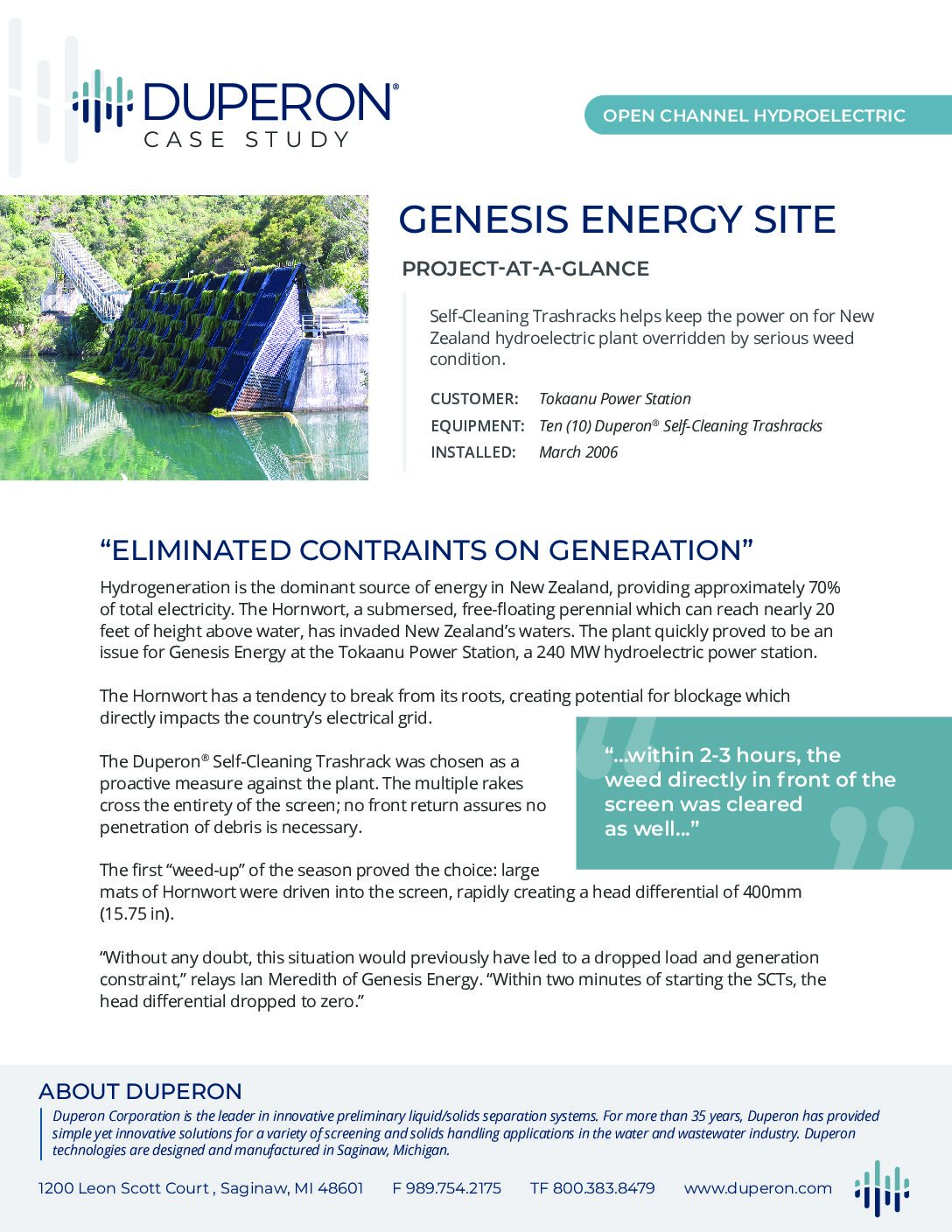

Genesis Energy Case Study

Self-Cleaning Trashracks helps keep the power on for New Zealand hydroelectric plant overridden by serious weed condition

Related Products

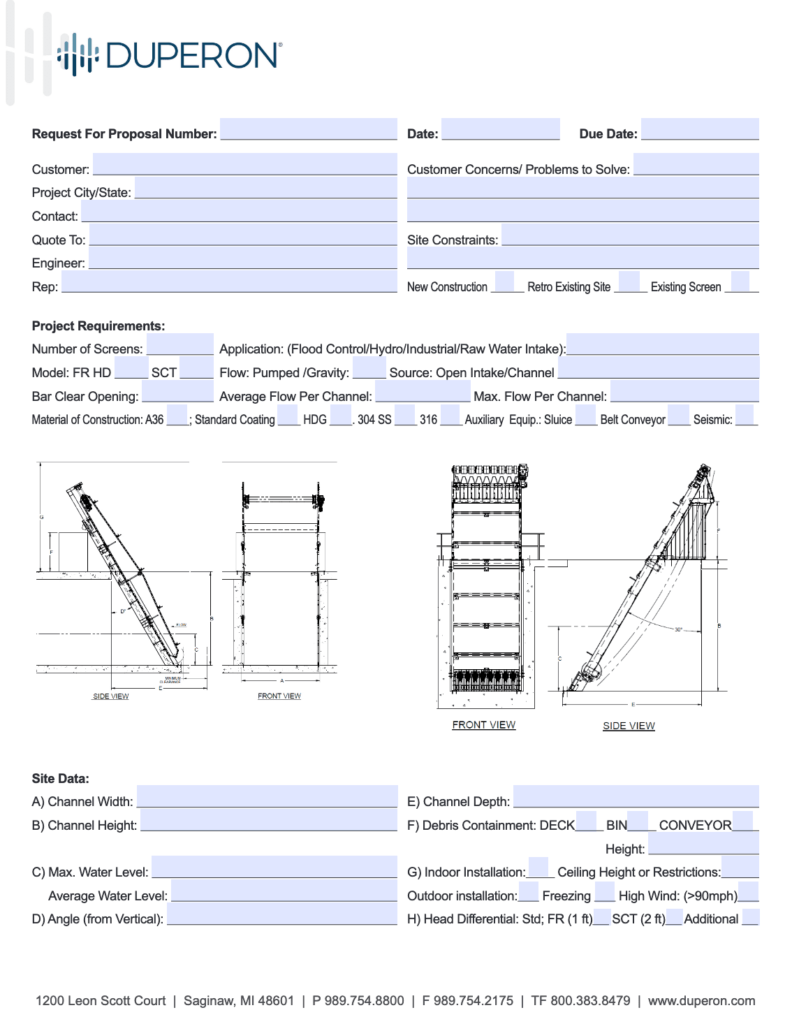

RFQ form

You’ll like

working with us

We have debris that varies from grass to very large tree trunks. The Duperon® Self-Cleaning Trashrack turned out to be a perfect fit for the intake, and the City of Dallas hasn’t looked back

Dhruv Pandya

City of Dallas District Manager

Department of Flood Control

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.