Harvest Rake

Mechanically Cleaned Bar Screens

A unique solution to manage high volumes of aquatic vegetation for algae harvesting and nutrient removal.

Introducing the Duperon Harvest Rake

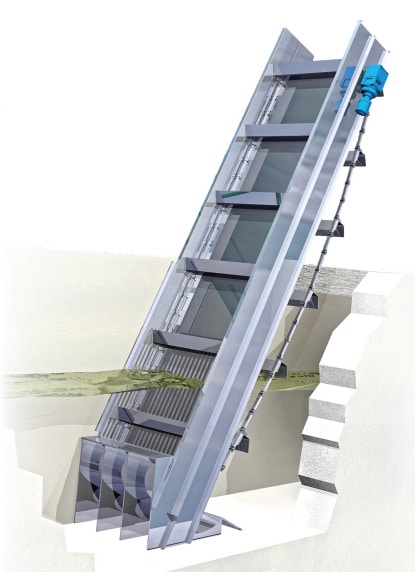

The Harvest Rake is an example of applying Duperon innovation to a unique need. It is specifically designed to manage high volumes of aquatic vegetation for algae harvesting and nutrient removal. It can also effectively remove large mats of long debris in open channel applications. The Harvest Rake offers a solution for sites that have side currents, backflow, or channel turbulence with the same flexibility, ease of operation, and simplicity expected from Duperon products.

Applications:

- Intakes for rivers with strong side currents

- Estuary protection

- Fish farming

- Algae harvesting

- Post–treatment for algae harvesting

- Nitrogen and phosphorus removal

The Duperon®

Difference

The Duperon®

Harvest Rake

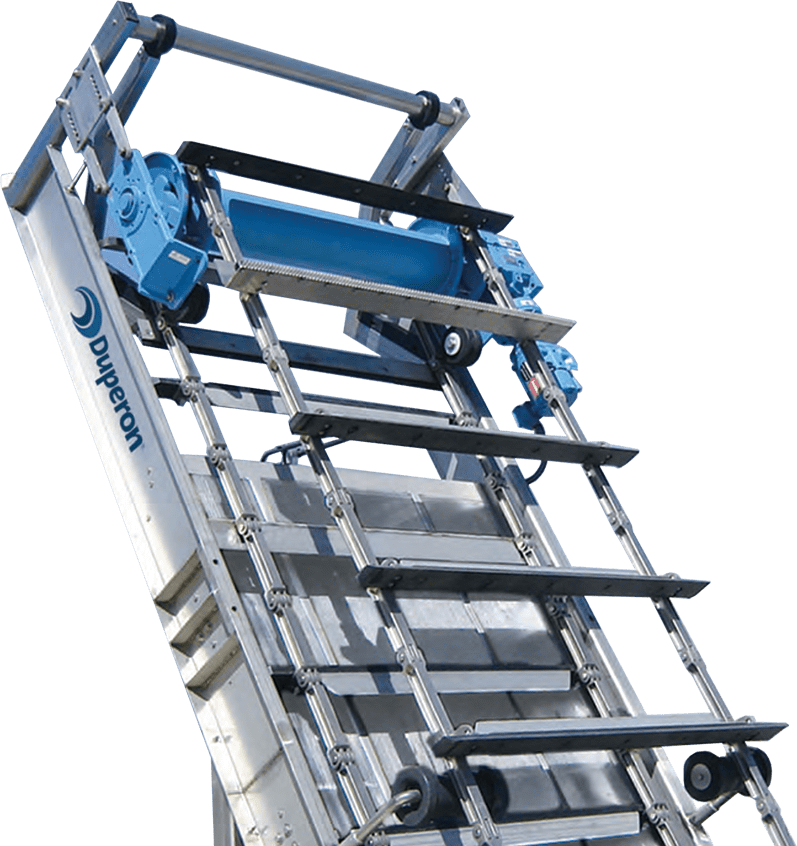

Simple operation

Front-clean, rear-return design with robust lifting capacity removes upstream debris without having to penetrate through a debris mat without shutdown.

Effective discharge

Uses the weight and mass of long stringy debris to simply roll off and self-discharge, eliminating the need for mechanical devices that can be problematic with aquatic debris. The discharge rate is designed to match process requirements.

Achieves harvesting or nutrient removal objectives

Designed to move matted aquatic vegetation that spans multiple scrapers (ie. long, stringy strands of algae or sheets of matted vegetation) for fish farming, algae harvesting, estuary protection and similar applications.

Duperon innovation

Nearly 40 years of partnering with our customers to solve their unique needs.

Description

The Harvest Rake is ideal for open channel applications with debris that may be long, stringy, or matted in clumps, such as vegetation or rags. Front-clean, rear-return technology utilizes proven FlexLink™ technology to assure effective debris capture without entanglement or wrapping.

General Specs

| Unit Width | 2 ft to 10 ft |

| Unit Length | 10 ft to 100 ft |

| Angle Of Installation | 20 to 45 degrees |

| Fine Screen Configuration | ¼ in, ⅜ in, and ½ in bar opening, tear-drop shaped bar, SSTL Thru-bar scrapers |

| Coarse Screen Configuration | ⅝ in to 4 in, rectangular shaped bar, UHMW-PE Thru-bar scrapers |

| Material Of Construction | 304 SSTL (standard), 316 SSTL & A36 Steel, Coated |

| Scraper Spacing | Every 4 links (standard) Every 2 link (option available for additional debris removal capacity) |

| Cleaning Frequency | Ranges from 1.2 discharges/min to 7 discharges/min (based on scraper spacing and site needs) |

| Flow Capacity | Engineered to your site |

| Lifting Capacity | 3,000 lbs |

| Typical Motor | 3 hp |

| Standard Controls | Packages range from simple start/stop to sophisticated automation. Motor overload protection provided. |

| Operation Options | Continuously/Manual, Automatic with timer, float, SCADA, differential/high-level sensing options with I/O as needed |

Key Features

A hybrid between a Self-Cleaning Trashrack and FlexRake®, the Harvest FlexRake® morphs tried and true Duperon-engineered designs into the ultimate aquatic vegetation removal solution.

- Lower Pump Bore Design ensures Mechanical Engagement and Eliminates Debris Bypass

- Ideal for Applications with Side Currents, Backflow or Channel Turbulence

- Unique Scraper Engagement Eliminates Debris Wrapping, Tangling and Allows for Easy Discharge

- Robust Lifting Capacity – Customized to Debris and Application

- Maintenance-Free Lower Bearing for the Life of the Equipment

Downloads

Related Products

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.