Municipal Wastewater

Treatment

Municipal wastewater screening to adapt to flow and debris conditions

Plant resiliency starts at the headworks – with screening made simple

Removing non-biological solids early in the wastewater treatment process translates into more efficient and reliable operation of downstream equipment. Thus, effective preliminary treatment is an important determinant of overall plant performance.

Duperon offers screening solutions and expertise to build wastewater plant resilience.

- It begins with simple, reliable, and adaptive screening that handles the unique conditions of your plant, with minimal downtime or maintenance.

- Removing the bulk of the solids allows the downstream treatment processes to operate as it should; problem-free, reducing operation and maintenance costs and ensuring process integrity.

- Screening improves the efficiency of biological and chemical wastewater treatment processes to meet regulations, NPDES permits and maintain environmental compliance.

- Washing and compacting cleans organic material from screenings allowing for more nutrients in the biological process and cleaner solids going to the landfill. Washer compactors also reduce disposal costs by reducing both volume and weight of screenings.

- All of which allows your team and resources to focus on other treatment demands.

More than 35 years ago, Duperon set out to build a better screening system. We learned about the known challenges and predictable results of existing options. By applying innovation, Duperon led the market to a new standard of simple, low maintenance and adaptable equipment with the invention of the FlexRake®.

Applications

Innovation remains a design standard as we continue to creatively solve problems and invent new products for liquid/solids separation applications:

- Headworks

- Preliminary treatment

- Septage receiving

- Sludge screening

- Combined Sewer Overflows (CSOs)

- Prisons

- Raw water intakes

- Piped influent

- Pump stations

- Lift stations

- Manholes

- Membrane Bioreactor (MBR) prescreening

- Algae screening (typically pre-disinfection)

Solutions to address the following

Every process has its unique challenges. Duperon engineers will work with you to achieve your specific process goals, while bringing decades of liquid/solids separation experience and know-how to the conversation in the following areas:

- Fine screens

- Coarse screens

- Mechanical bar screens

- Perforated screens

- Drum screens

- Flushable wipes removal

- Washing compacting

- Debris handling

- Conveyance

The Duperon®

Difference

Partnership

‘You’ll like working with us’ is a commitment and way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs

Process resilience

Effective solids removal through a broad range of flow and debris conditions so downstream assets remain protected

Reliable operation

Duperon adaptive technologies handles grease, grit, first flushes, rags, large or unusual debris (like 2x4s, bricks or sewer plugs) without shutdown or operator intervention

Low cost of ownership

With few parts and minimal maintenance required, Duperon equipment is easy to install, own and operate

Ongoing Innovation

You can count on continuous development of products that are responsive, intelligent and meet the demands of your plant now and in the future

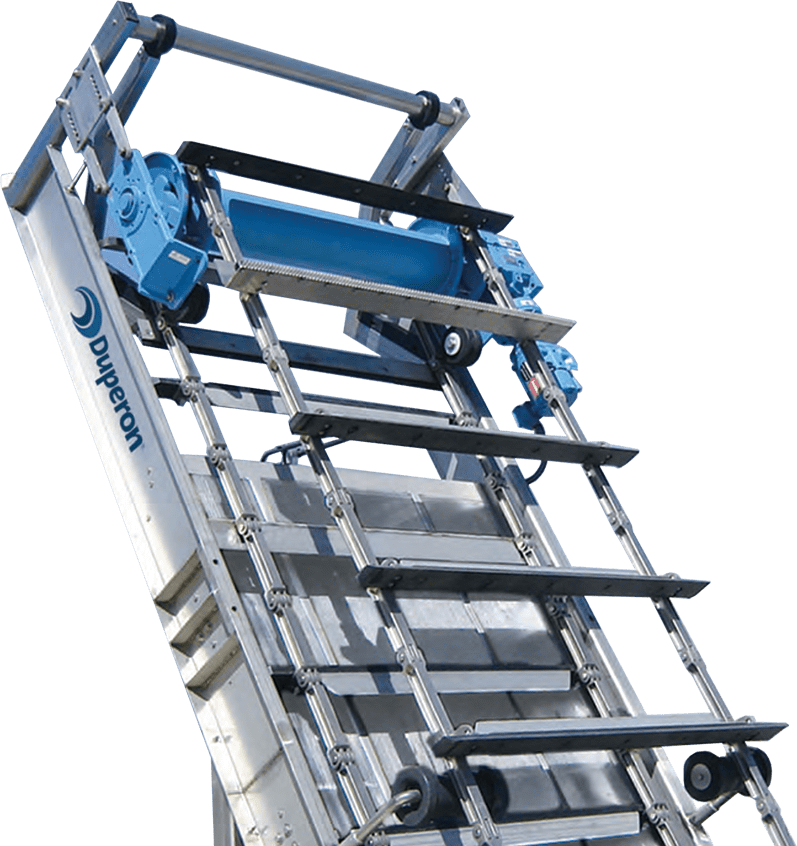

Coarse Screening

Bar openings greater than ½ in

Preliminary treatment screening. Pump protection.

Fine Screening

Openings ½ in down to 0.020 in

Solids removal before secondary or tertiary treatment.

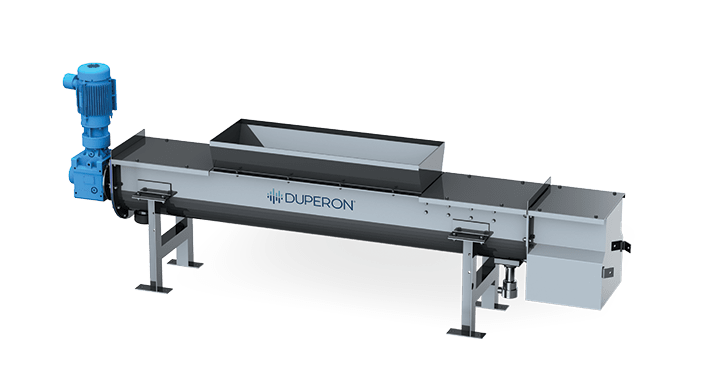

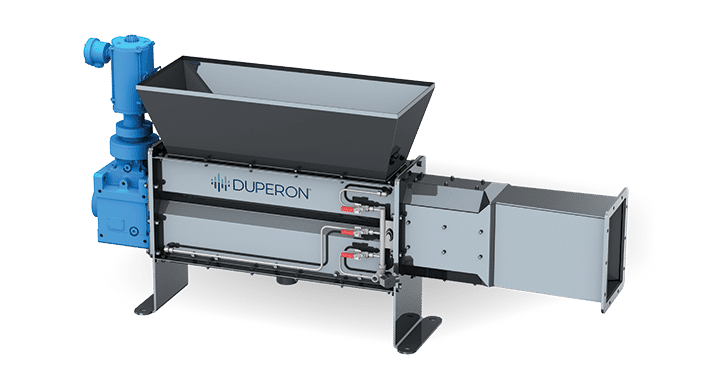

Debris Management

Collection and Conveyance

Processing and transport of collected screenings.

You’ll like

working with us

Top notch in simplicity and reliability

Jim Kerezman

WWTP Superintendent, Goshen Wastewater Treatment Plant

Goshen, Indiana

Municipal Wastewater Treatment Products

By employing liquid/solids separation technology, inorganic materials can easily be removed at the headworks and effectively prevent costly downstream disruptions. Proper screening at the influent protects your processes, improves system sustainability and overall life-cycle costs. Solids handling equipment is also available for a fully automated system.

Products quick guide

| Product Name | Screen Type | Bar Opening | Bar Type | Engineering |

|---|---|---|---|---|

| Dual Auger System | Coarse | ~¾ in | Slotted Bar, SSTL | Pre- Engineered |

| FlexRake® IQ™ | Coarse & Fine | ⅛ in to 4 in | Slotted Bar, SSTL | Site Specific |

| FlexRake® IQ2™ | Coarse & Fine | ¼ in – 4 in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Full Penetration Fine Screen | Fine | ¼ in to ½ in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Full Penetration | Coarse | Greater than ½ in | Slotted Bar, SSTL | Site Specific |

| FlexRake® Heavy Duty | Coarse | 2 in – 4 in | Slotted Bar, SSTL in wastewater | Site Specific |

| FlexRake® Low Flow | ¼ inch, ½ inch, ¾ inch, 1 inch | Removable Bar, SSTL | Pre- Engineered |

Tell us about your project

Do you have a liquid/solids separation challenge for a wastewater application? Let’s solve it together.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.