FlexRake® GTS

Global Technology Screen

¼ in – ½ in bar openings

The advantage of FlexRake® Adaptive Technology™ for high solids applications

Cost-effective screening for low flow, high solids applications

The FlexRake® GTS is designed to serve septage receiving stations, prisons, nursing homes, hospitals, and other applications with heavy solids loading. It is a fine bar screen available in ¼ inch, ⅜ inch and ½ inch openings. There are in-channel and tank models (piped-in, piped-out) options.

Our story is simple

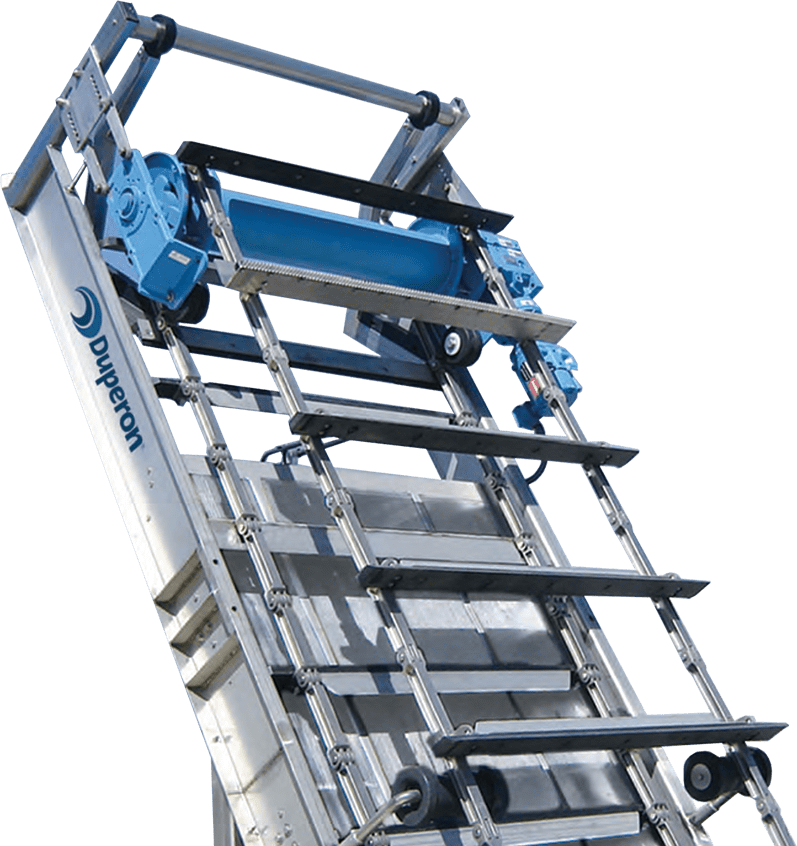

The FlexRake GTS – Global Technology Screen has three unique product offerings for low flow screening applications but with a unique value proposition for customers with sites that have heavy solids loading. As has been consistent with the history of Duperon Corporations ability to invent, the GTS modified its Jam Evasion™ Technology with a fixed drive head that can be adjusted to site conditions, flex/pivot around large debris all while assuring the engagement into the screen to provide critical movement of heavy solids concentrations. These features allow a plant or facility with very difficult conditions such as a system ‘flush’ to dry or minimal flows to operate without issue.

Applications:

- Septage receiving

- Prisons

- Nursing homes

- Hospitals

- And other low flow, high solids applications

The Duperon®

Difference

The Duperon®

FlexRake® GTS

Automated solution

Simple and cost-effective mechanical bar screen option for low flow, high solids sites

Proven FlexRake technology

Adapts to a range of unpredictable flow and debris conditions without shutdown or operator intervention

Low cost of ownership

With few parts, a fractional horsepower motor, and minimal maintenance, the FlexRake GTS is easy to install, own, and operate by your crew

Designed for duty

Engineered to perform in fine screening applications that have low flows and high solids loading

Optimized engagement

Specially designed drivehead is site-adjustable to allow Jam Evasion™ to flex/pivot around debris and also ensures optimal engagement in the screen to avoid blinding in heavy solid conditions

Tank models available

Piped-in, piped-out option for sites that don’t have channel infrastructure

Description

The FlexRake® GTS is a simple front-clean, front-return mechanical bar screen. It features the SmartLink™ multifunctional link system, which eliminates underwater sprockets, bearings or tracks that create a fixed path of travel and are subject to fouling and/or jamming. The SmartLink design is engineered for long product life and has no minimal water level requirements. The groundbreaking Jam Evasion™ Technology allows the FlexRake GTS to flex/pivot to remove irregular debris or high solids gluts (i.e. bedsheets, jumpsuits, adult wipes, etc).

General Specs

| Typical Applications | Septage receiving

Prisons Hospitals Nursing homes And other low flow, high solids applications |

| Unit Width | 18 in to 4 ft

Single strand unit available 18 in to 24 in |

| Channel Height | 2 ft to 8 ft |

| Bar Openings | ¼ in, ⅜ in, and ½ in |

| Bar Shape | Tear-drop shaped, welded bar screen |

| Scraper Configuration | SSTL Thru-Bar™ scrapers that clean all sides of the bar and the cross member |

| Material of Construction | Available in 304 or 316 Stainless Steel |

| Flow Capacity | Designed to your site |

| Cleaning Frequency | 1 discharge/minute on low

5 discharges/minute on high |

| Lifting Capacity | 500 lbs |

| Angle of Installation | 10 – 30 degrees (from vertical), dependent upon site conditions |

| Typical Motor | ½ hp inverter duty, explosion proof |

| Standard Controls | Packages range from simple start/stop to sophisticated automation.

Motor overload protection provided. |

| Operation Options | Continuous/Manual

Automatic with timer, float, SCADA, differential/high-level sensing options with I/O as needed |

Key Features

Tear-drop shaped welded bars provide highest efficiency in the industry; 25%-50% more efficient (depending on the bar opening)

SSTL Thru-Bar™ scrapers clean all three sides of the bar and cross member

Proven Duperon® FlexRake® technology: no lower bearings, sprockets, jam points or confined space entries

UHMW & SSTL SmartLink™ is completely corrosion-resistant, provides long life and is self-lubricating material

UHMW and SSTL SmartLink allows for “dry” operation which is ideal for low flow sites with varying water levels since there is no minimum depth required

Schematic

Photo Gallery

Case Studies

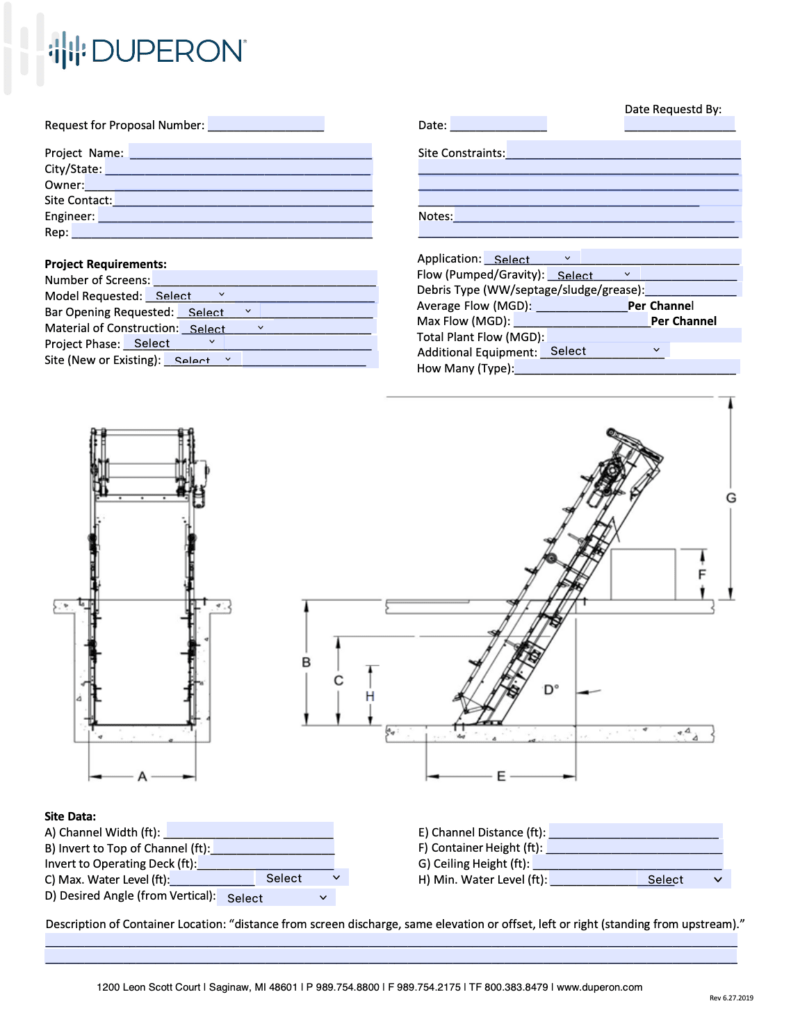

RFQ form

You’ll like

working with us

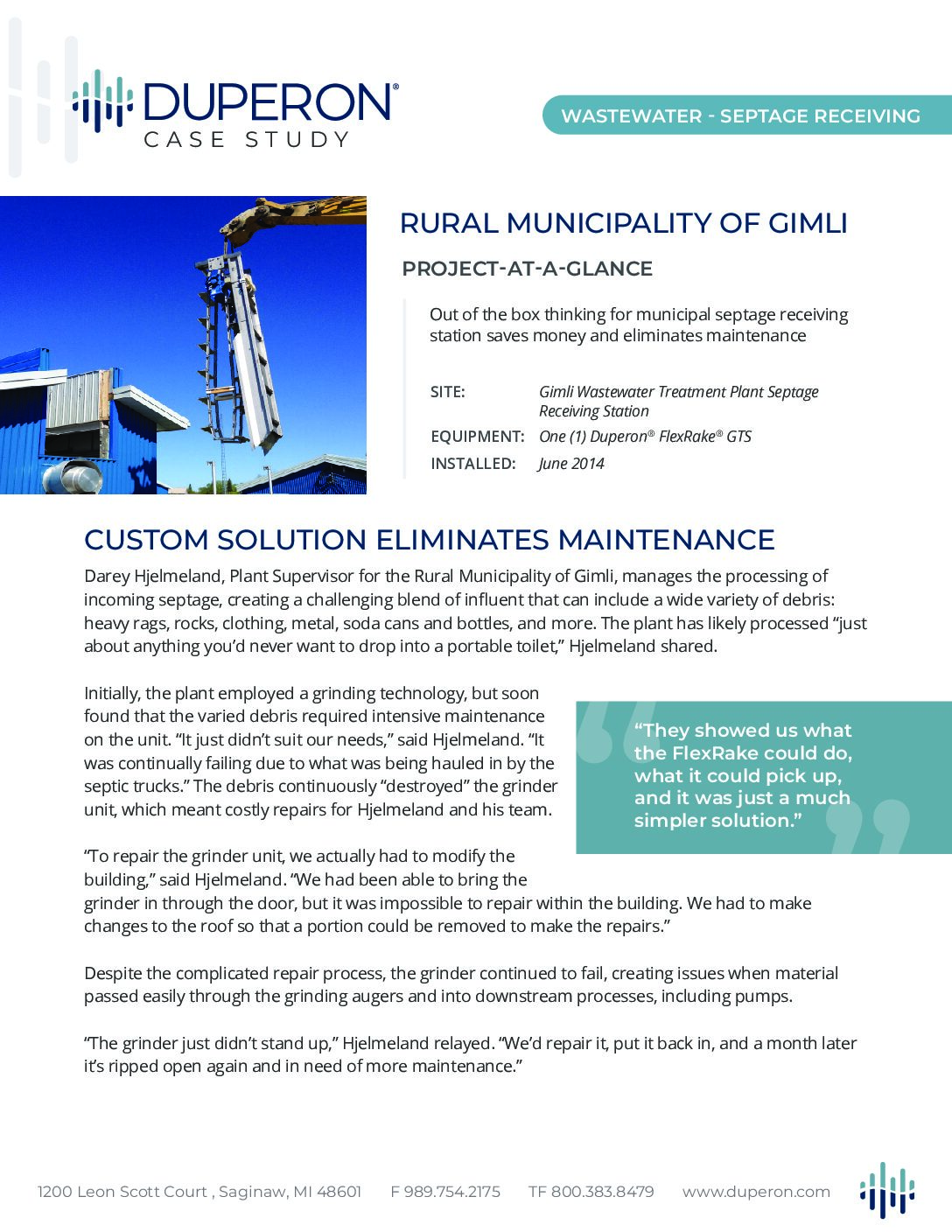

Since the installation of the Duperon® FlexRake® GTS there have been no issues downstream. It has been so much better, even better than we expected. There are no maintenance issues anymore

Darey Hjelmeland

Plant Supervisor, Rural Municipality of Gimli

Tell us about your project

‘You’ll like working with us’ is a commitment and the way we deliver extraordinary customer care for the full life-cycle of your equipment. This is how we strive to earn the privilege to serve your continued screening needs.

Design Collaboration

To build your solution, our engineers take the time to understand your facility, process, and goals.

We’ll combine our team’s experience with water screening, cleaning, and processing with your team’s detailed understanding of your product and process, so we can develop a reliable and cost-effective solution.